1857年英国物理学家William Thomson[1]发现磁电阻效应,但因其变化率不足千分之三而未能引起足够的重视。1988年Peter Grunberg[2]和Albert Fert[3]各自独立地发现了巨磁阻效应(GMR效应),Fe/Cr/Fe三层膜和Fe/Cr多层膜系统的室温磁电阻变化率达到1.5%,在4.2K的低温下甚至达到50%。后来在颗粒膜[4,5]中也发现了GMR效应,类钙钛矿结构[6]的稀土锰氧化物薄膜的室温磁电阻变化率高达60%(庞磁电阻效应,CMR效应),还发现了隧道磁电阻效应(TMR) [7,8,9,10,11,12]。GMR效应的发现,为现代电子行业开发和利用基于巨磁阻效应的磁传感器、磁头、磁随机存储器等各类先进的商业电子产品奠定了基础。

1 实验方法

实验用自旋阀多层膜结构包括Ta/CoFe/Fe/Au/Fe/IrMn/Ta和Ta/CoFe1/Au/CoFe2/IrMn/Ta。使用2英寸表面热氧化的SiO2/Si衬底,氧化层的厚度约为500 nm。溅射沉积前先充分清洗衬底,然后用氮气枪吹干后转移到溅射腔中备用。

实验中使用的靶材有CoFe (99.95%,质量分数,下同)、Fe (99.99%)、IrMn (99.95%)、Ta (99.95%)和Au (99.99%);工作气体为高纯氩气(99.999%),气流量为20 sccm,溅射压强约为0.5 Pa,靶基距为10 cm。溅射前先将本底抽真空到1×10-5 Pa以下,然后接通工作气体。在溅射过程中通过改变每一种材料的溅射时间来控制各层薄膜的厚度,从而调控自旋阀多层膜的性能。典型的自旋阀多层膜样品的制备参数,列于表1。为了引入参考场,将样品放入真空磁性退火炉中进行加磁场退火,退火温度约280℃,保温时间约30 min,自然冷却。

表1 典型样品的溅射工艺参数

Table 1

| No. of sample | Structure | Power/W | d / nm |

|---|---|---|---|

| I | Ta/CoFe/Fe/Au/Fe/IrMn/Ta | 45 | 20/20/20/8/20/30/20 |

| II | Ta/CoFe1/Au/CoFe2/IrMn/Ta | 25 | 6/6/1.9~5.8/6/9/6 |

| III | Ta/CoFe1/Au/CoFe2/IrMn/Ta | 25 | 6/6/3.8/6/5.4~10.8/6 |

| IV | Ta/CoFe1/Au/CoFe2/IrMn/Ta | 25 | 6/3.6~8.4/3.8/8.4~3.6/9/6 |

用透射电子显微镜(TEM)观测多层薄膜样品的横截面形貌;用四探针法[17]测量样品的磁阻曲线;用振动样品磁强计(VSM)测量样品的面内/面外磁滞回线。

2 实验结果

2.1 样品I的自旋阀结构

图1

2.2 隔离层(Au)对自旋阀MR的影响

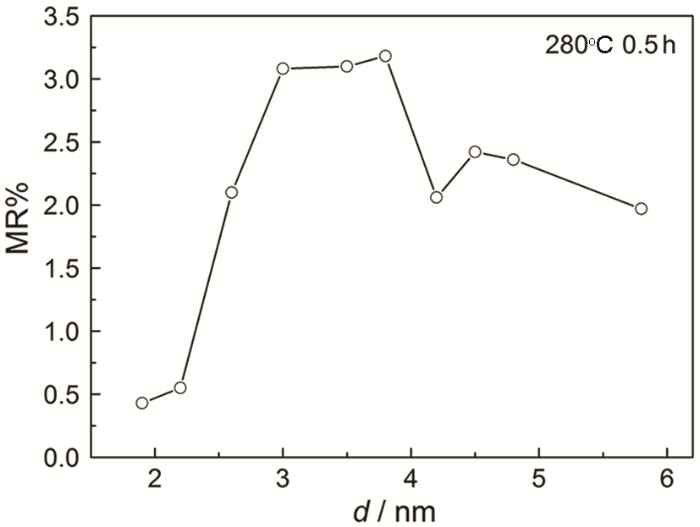

磁电阻变化率(MR值)是自旋阀(SV)的重要参数之一,但是样品I的Ta/CoFe/Fe/Au/Fe/IrMn/Ta的MR值却很小(<1%)。为了便于研究,制备了Ta/CoFe1/Au/CoFe2/IrMn/Ta系列样品以简化多层膜中的功能层,并先调控隔离层Au的厚度。隔离层是SV中的关键,只有隔离层Au起到隔离自由层和被钉扎层的作用,才能降低磁性多层膜之间的交换耦合作用,使自由层的磁化翻转不受被钉扎层的影响,从而得到较大的磁电阻变化率。图2给出了样品II系列Ta/CoFe1/Au(2~6 nm)/CoFe2/IrMn/Ta的MR值随隔离层Au厚度变化的特性曲线。

图2

图2

不同Au层厚度对样品II系列自旋阀磁电阻的影响

Fig.2

MR% under different IrMn layer thickness for Sample II

样品的MR值随隔离层厚度的增大呈现阻尼振荡衰减的趋势,其根源在于隔离层的存在使得自由层和被钉扎层之间的交换耦合强度在幅值上呈现阻尼振荡效应[18]。太薄的隔离层,Au厚度小于2.6 nm,不利于其上被钉扎层晶格的形成,导致自由层与被钉扎层间耦合增强,不利于两磁性层的先后翻转,因此MR值较小;当隔离层Au厚度为3.8 nm时,MR值达到最大值。Au隔离层厚度继续增大达到4.5 nm时,MR值达到稍小的另一个极大值;Au层厚度继续增大使Au层内部的分流作用增大减弱反铁磁耦合,导致MR值下降。这些结果表明,Au层溅射时间12 s(厚度约为3.8 nm)是最佳条件,因此后续样品III和样品IV都以此为标准。

2.3 钉扎层(IrMn)对自旋阀MR的影响

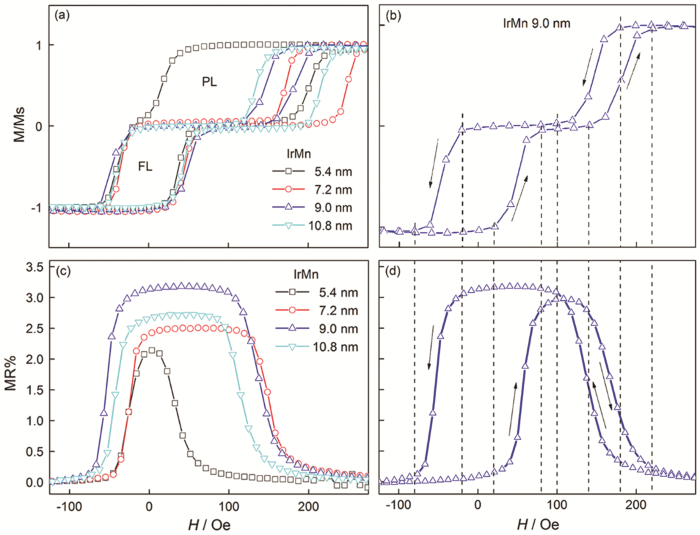

钉扎层的作用是调控被钉扎层的磁化翻转,使其磁化中心偏离原点,使被钉扎层与自由层磁化翻转不同步,从而引入参考场,调控磁电阻的变化过程。具有不同钉扎层厚度的样品III系列[Ta(6 nm)/CoFe1(6 nm)/Au(3.8 nm)/CoFe2(6 nm)/IrMn (5.4~10.8 nm)/Ta(6 nm)]的磁滞回线和磁电阻特性曲线,如图3所示。图3a给出了样品III系列的磁滞回线,每条磁滞回线都由两个小回线组成,其中左下角的小回线是自由层(FL)CoFe1的磁滞回线,而右上角的小回线则是被钉扎层(PL)CoFe2的磁滞回线。由图3a可知,虽然IrMn层厚度增加FL的磁滞回线基本上没有太大的改变,可见隔离层Au确实起到了很好的隔离作用,使得自由层几乎不受IrMn钉扎层厚度的影响。另一方面,随着IrMn层厚度的增大PL的交换偏置场位置先右移再左移再右移,被钉扎层的矫顽力先减小后增大。当IrMn层厚度为9 nm时样品的交换偏置场最大,被钉扎层的矫顽力最小,性能最优。对应到图3c中磁电阻值随IrMn层厚度的变化中,当IrMn层厚度为9 nm时样品的MR值也最大,实现了磁滞回线与MR值变化之间的完美匹配。

图3

图3

样品III系列自旋阀的磁滞回线和磁阻特性曲线

Fig.3

Hysteresis loop under different IrMn layer thickness (a), hysteresis loop of irmn layer 12 nm (b), magnetic resistance characteristic curve under different irmn layer thickness (c) and magnetic resistance characteristic curve of IrMn layer 12 nm (d) of sample III

2.4 自由层(CoFe1)和被钉扎层(CoFe2)对自旋阀MR的影响

在SV的功能层中,除了隔离层和钉扎层,自由层和被钉扎层的相对厚度也影响SV的性能。样品IV系列就是通过改变溅射时间调控了自由层和被钉扎层的相对厚度,其磁滞回线和磁电阻变化曲线如图4所示。图4a给出了样品IV系列的磁滞回线。可以看出,一方面,随着自由层与被钉扎层厚度的增加两者的饱和磁化强度均增大;另一方面,自由层矫顽力大小随着其厚度的增加而增大,被钉扎层矫顽力大小随着其厚度的增加而减小。图4b给出了样品IV系列的磁电阻变化曲线,其磁电阻变化过程与图4a中磁化翻转过程匹配良好。可以看出,随着自由层厚度的增加、被钉扎层厚度的减小,MR值呈现一个先增大后减小的趋势。当自由层与被钉扎层溅射时间均为50 s时自由层与被钉扎层厚度为6 nm,两者的的饱和磁化强度相当而MR值最大。

图4

图4

样品IV系列自旋阀的磁滞回线和磁阻特性曲线

Fig.4

Hysteresis loop under different CoFe1, CoFe2 layer thickness (a) and magnetic resistance characteristic curve under different CoFe1, CoFe2 layer thickness (b) of sample IV

总之,随着自由层厚度的增加、被钉扎层厚度的减小,自由层与被钉扎层矫顽力均增大,两者的饱和磁化强度之间的差异呈现先减小后增大的趋势,样品的MR值与两者的饱和磁化强度的差值成反比,呈现出先增大后减小的变化规律。

3 结论

(1) 对于自旋阀结构(Ta/CoFe1/Au/CoFe2/IrMn/Ta),Au隔离层的溅射时间为12 s时,厚度约3.8 nm,样品磁电阻变化率最大。随着Au隔离层溅射时间(厚度)的增加,样品MR值呈现振荡衰减的趋势。改变溅射时间可实现对Au隔离层厚度的调控,实则是其隔离作用与分流作用之间的竞争关系的一个调控。

(2) IrMn钉扎层的厚度为9 nm的样品,具有最佳MR值。样品的MR值随着被钉扎层矫顽力的增大而增大,被钉扎层矫顽力最小的样品,具有最高的MR值。

(3) 自由层(CoFe1)、被钉扎层(CoFe2)的厚度为6 nm/6 nm时的样品,其磁电阻变化率最大。自由层与被钉扎层厚度差异越小,两者的饱和磁化强度差异越小,则MR值越高。

参考文献

On the Electro-dynamic qualities of metals: -effects of magnetization on the electric conductivity of nickel and of iron

[J].

Enhanced magnetoresistance in layered magnetic structures with antiferromagnetic interlayer exchange

[J].

Giant magnetoresistance of (001)Fe/(001)Cr magnetic superlattices

[J].

Giant magnetoresistance in heterogeneous Cu-Co alloys

[J].

Giant magnetoresistance in nonmultilayer magnetic systems

[J].

Giant negative magnetoresistance in perovskitelike La2/3Ba1/3MnOx ferromagnetic films

[J].

Giant magnetic tunneling effect in Fe/Al2O3 /Fe junction

[J].

Spin-dependent tunneling conductance of Fe/MgO/Fe sandwiches

[J].

Theory of tunneling magnetoresistance of an epitaxial Fe/MgO/Fe(001) junction

[J].

Giant room-temperature magnetoresistance in single-crystal Fe/MgO/Fe magnetic tunnel junctions

[J].The tunnel magnetoresistance (TMR) effect in magnetic tunnel junctions (MTJs) is the key to developing magnetoresistive random-access-memory (MRAM), magnetic sensors and novel programmable logic devices. Conventional MTJs with an amorphous aluminium oxide tunnel barrier, which have been extensively studied for device applications, exhibit a magnetoresistance ratio up to 70% at room temperature. This low magnetoresistance seriously limits the feasibility of spintronics devices. Here, we report a giant MR ratio up to 180% at room temperature in single-crystal Fe/MgO/Fe MTJs. The origin of this enormous TMR effect is coherent spin-polarized tunnelling, where the symmetry of electron wave functions plays an important role. Moreover, we observed that their tunnel magnetoresistance oscillates as a function of tunnel barrier thickness, indicating that coherency of wave functions is conserved across the tunnel barrier. The coherent TMR effect is a key to making spintronic devices with novel quantum-mechanical functions, and to developing gigabit-scale MRAM.

Giant tunnelling magnetoresistance at room temperature with MgO (100) tunnel barriers

[J].Magnetically engineered magnetic tunnel junctions (MTJs) show promise as non-volatile storage cells in high-performance solid-state magnetic random access memories (MRAM). The performance of these devices is currently limited by the modest (&lt; approximately 70%) room-temperature tunnelling magnetoresistance (TMR) of technologically relevant MTJs. Much higher TMR values have been theoretically predicted for perfectly ordered (100) oriented single-crystalline Fe/MgO/Fe MTJs. Here we show that sputter-deposited polycrystalline MTJs grown on an amorphous underlayer, but with highly oriented (100) MgO tunnel barriers and CoFe electrodes, exhibit TMR values of up to approximately 220% at room temperature and approximately 300% at low temperatures. Consistent with these high TMR values, superconducting tunnelling spectroscopy experiments indicate that the tunnelling current has a very high spin polarization of approximately 85%, which rivals that previously observed only using half-metallic ferromagnets. Such high values of spin polarization and TMR in readily manufactureable and highly thermally stable devices (up to 400 degrees C) will accelerate the development of new families of spintronic devices.

A perpendicular-anisotropy CoFeB-MgO magnetic tunnel junction

[J].Magnetic tunnel junctions (MTJs) with ferromagnetic electrodes possessing a perpendicular magnetic easy axis are of great interest as they have a potential for realizing next-generation high-density non-volatile memory and logic chips with high thermal stability and low critical current for current-induced magnetization switching. To attain perpendicular anisotropy, a number of material systems have been explored as electrodes, which include rare-earth/transition-metal alloys, L1(0)-ordered (Co, Fe)-Pt alloys and Co/(Pd, Pt) multilayers. However, none of them so far satisfy high thermal stability at reduced dimension, low-current current-induced magnetization switching and high tunnel magnetoresistance ratio all at the same time. Here, we use interfacial perpendicular anisotropy between the ferromagnetic electrodes and the tunnel barrier of the MTJ by employing the material combination of CoFeB-MgO, a system widely adopted to produce a giant tunnel magnetoresistance ratio in MTJs with in-plane anisotropy. This approach requires no material other than those used in conventional in-plane-anisotropy MTJs. The perpendicular MTJs consisting of Ta/CoFeB/MgO/CoFeB/Ta show a high tunnel magnetoresistance ratio, over 120%, high thermal stability at dimension as low as 40 nm diameter and a low switching current of 49 microA.

Review of Current sensor technology based on giant magneto resistive effect and possible applications for smart grids

[J].

基于巨磁电阻效应的电流传感器技术及在智能电网中的应用前景

[J].介绍智能电网中电流的传感和量测技术发展的要求和新趋势,阐述智能电网中各种电流传感器的原理和特点,比较了传统电磁式电流传感器(如CT,罗氏线圈,霍尔)和几种新型的电流传感器(如光纤,巨磁电阻)的优缺点。在分析智能电网的电流测量需求的基础上,结合巨磁电阻(giant magneto resistive,GMR)电流传感器的研究内容着重展望了GMR电流传感器在智能电网中的应用前景。最后总结了GMR传感器在智能电网测量应用中的优势和不足,并针对这些不足,指出了后续研究的方向。

Study of a novel biosensor based on GMR effect

[J].

基于GMR效应的新型生物传感器研究

[J].

The Electrical Conductivity of Transition Metals

[J].

Magnetoresistive sensor based on the spin valve effect

[P].

Tune the MR of spin valve by using the pinned layer

[J].

利用被钉扎层调控自旋阀的磁电阻值

[J].