随着能源危机和环境问题的日趋严重,节能、降耗、环保和安全成为汽车行业发展的核心问题。在较低成本和良好工艺的前提下,开发兼具高强度和优异塑性的高强钢成为汽车钢板领域的发展目标。中锰TRIP钢作为第三代先进高强钢的典型代表材料之一,引起了国内外学者的关注[1]。针对中锰钢的热处理工艺、合金元素添加以及微观组织的优化,学者们开展了相关研究以期使中锰钢的性能接近或达到高锰TWIP钢的级别(强塑积大于50 GPa∙%)。例如,Park等[2]制备的Fe-0.23C-8.1Mn-5.3Al冷轧中锰钢的抗拉强度为949 MPa,总延伸率为54%(强塑积超过50 GPa∙%)。Cai等[3]发现,将Fe-0.18C-11Mn-3.8Al钢热轧和在两相区退火后其强塑积接近66 GPa∙%。提高中锰TRIP钢中的Al、C、Mn元素的含量,可在较大范围内提高钢板的强塑积水平。但是,较高的C、Mn含量使钢板的焊接性能恶化。在钢中添加过多的Al元素(含量高于2%)不仅使成本提高,在冶炼过程中还容易引起冒口堵塞和生成非金属夹杂物。因此,在降低上述元素含量的前提下进一步提高中锰TRIP钢的强度和塑性,成为一个攻关难点。

1 实验方法

实验用钢使用50kg真空感应炉熔炼,其主要化学成分(%, 质量分数)为:0.18 C,7.8Mn,1.65Al,0.04Ce,Fe余量。为了防止退火过程中晶粒异常长大和净化钢质,添加微量的稀土Ce。

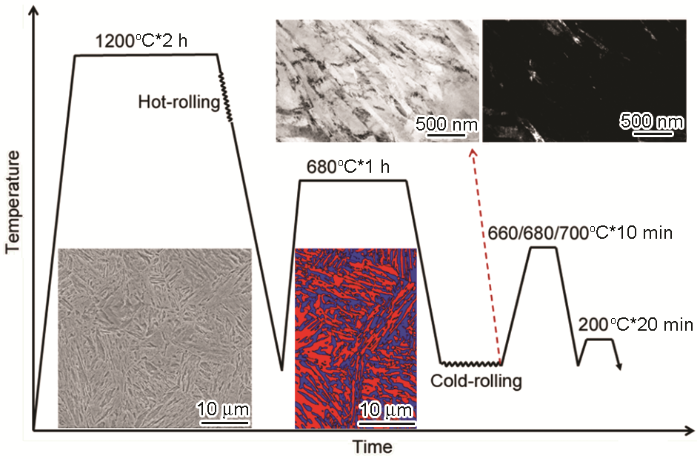

将熔炼好的钢锭去冒口、扒皮,加热至1200℃保温2 h后锻造成厚度为30 mm 的方坯,终锻温度不低于900℃。将锻坯重新加热至1200℃,保温2 h后热轧至4 mm厚,然后空冷至室温。为了产生异质结构和便于冷轧,将热轧钢板在680℃保温1 h后空冷至室温,将其酸洗后冷轧至2.2 mm。再将冷轧钢板分别加热至660℃、680℃、700℃保温10 min后空冷至室温,然后在200℃下回火20 min。为了方便叙述,将上述3个试样依次编号为A66、A68、A70。

沿着轧制方向截取拉伸试样,标距为50 mm,宽度12.5 mm。在WDW-100型实验机上进行室温拉伸实验,拉伸速率为3 mm/min。在Sigma 500型实验机上实施原位EBSD测试,测试电压为20 kV,步长为50 nm,拉伸速率为10-3 s-1,试样的前处理为机械抛光。使用配备Cu靶的D/Max-2200型X射线衍射仪(XRD)检测分析不同制备工艺试样的奥氏体含量,扫描速率为2°/min,扫描范围40°~110°。用对比法计算奥氏体含量[8],其中BCC相的衍射峰选择(200)和(211),FCC相衍射峰选择(200)、(220)和(311)。采用EBSD及ACTEM技术分析不同退火与回火试样的微观组织形貌,其中EBSD在FEI Quanta 650 FEG型场发射扫描电镜上完成,分析前试样分别经过机械抛光与电解抛光(7%高氯酸与93%酒精混合溶液)。在配备能谱的Titan Cubed Themis G2 300型设备上完成ACTEM[9]。

2 实验结果

2.1 力学性能和显微组织

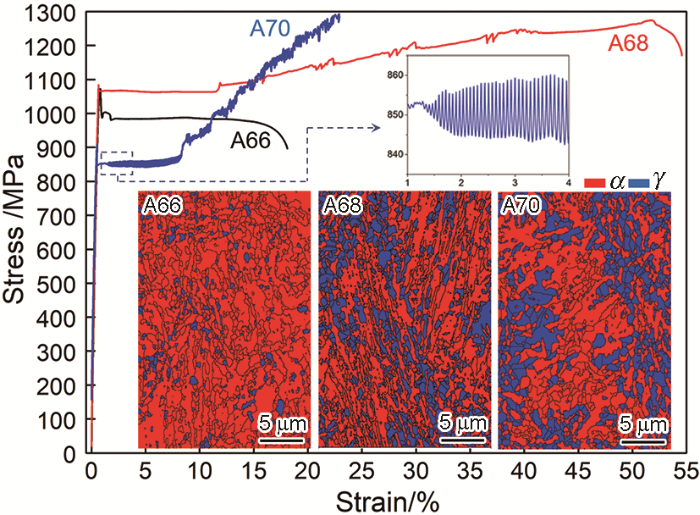

图1和表1给出了在不同温度退火和回火试样的拉伸性能曲线和测试结果。可以看出,A68与A70试样的强塑积均达到第三代先进高强钢的级别(>30 GPa∙%),其中A68试样的强塑积高达69.3 GPa∙%。实验结果表明,退火温度对中锰TRIP钢性能具有重要影响。退火温度由660℃提高到680℃和700℃,钢板的屈服强度(YS)分别由980 MPa升高至1060 MPa然后降至849 MPa,而抗拉强度(UTS)由1072 MPa提高到1272 MPa和1298 MPa,总延伸率(TE)与强塑积的变化趋势相同,由18.1%增至54.5%而后降低到23.5%。同时,从图1可见,三种试样的拉伸曲线形态迥异。A70试样屈服伊始出现与TRIP效应相关的锯齿状曲线[10],说明屈服后很快发生奥氏体相变,即奥氏体稳定性较差;A66试样在拉伸过程中未见锯齿形态,且加工硬化能力较弱,表明奥氏体相变不明显。A68试样较大范围内出现明显的锯齿形态,表明其奥氏体稳定性有一定分散性,可在较大的应变范围内连续发生TRIP效应。

图1

图1

不同退火试样的工程应力应变曲线

Fig.1

Engineering stress-strain curves of the present steels annealed at different temperature

表1 退火和回火处理后试验钢的拉伸测试结果

Table 1

YS /MPa | UTS /MPa | TE /MPa | PSE /GPa∙% | Volume fraction of γ/% | Average grain size of γ/μm | ||

|---|---|---|---|---|---|---|---|

| EBSD | XRD | ||||||

| A66 | 980 | 1072 | 18.1 | 19.4 | 8.3 | 21.1 | 0.33 |

| A68 | 1060 | 1272 | 54.5 | 69.3 | 34 | 36.3 | 0.41 |

| A70 | 849 | 1298 | 23.5 | 30.5 | 42 | 41.3 | 0.67 |

图1给出了在不同温度退火与回火试样微观组织的EBSD形貌,其中红色代表铁素体,蓝色代表奥氏体。可以看出,三种实验钢微观组织差别显著。随着退火温度的提高钢中的奥氏体含量逐渐增加,其平均晶粒尺寸亦有所增大。结合表1可知,A66试样的奥氏体平均晶粒尺寸为0.33 μm,退火温度提高到680℃与700℃该值分别增加至0.41 μm与0.67 μm。实验结果表明,A66试样的奥氏体以小颗粒状为主,A70试样的奥氏体以尺寸较大的块状形貌为主,而A68试样表现为多形貌,多尺寸的异质奥氏体形态,其中主要包括小颗粒状、大块状以及片层状奥氏体。同时,根据表1,对于A66试样,EBSD与XRD奥氏体含量测试结果差别较大,而A68与A70试样的两种测试结果比较吻合。其原因是,EBSD步长50 nm,A66试样中小奥氏体颗粒(<1 μm)难以被EBSD所捕捉,但是可以被XRD测量,因此EBSD测试结果比XRD的结果低。

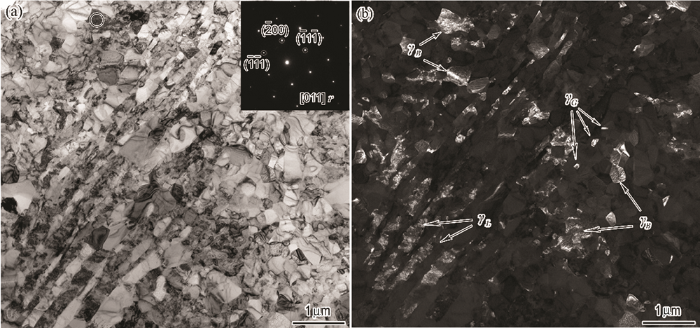

图2

图2

A68试样的TEM微观组织形貌

Fig.2

TEM investigations of retained austenite in specimen A68 (a) Bright field image (b) Austenite dark field image of Fig.a

2.2 在异质中锰TRIP钢拉伸过程中微观组织的演变

图3

图3

A68试样拉伸过程中微观结构的演变

Fig.3

Interrupted in situ EBSD of sample A68 deformed at tensile strains of 0%~40% (a) phase map and (b) KAM map of FCC γ grain. (c) Inverse pole figure (IPF) of γ

根据图3a1(未拉伸状态相图),A68试样基体中包含片层状、颗粒状及块状奥氏体组织,与EBSD和TEM分析结果吻合。随着应变增大至8%(图3a2)其微观组织变化不大,仅个别小颗粒状的奥氏体发生马氏体相变。但是,将图3b1与3b2对比,在应变8%试样的基体中小颗粒状奥氏体、片层状奥氏体以及相界/晶界附近的块状奥氏体的KAM值有所增加,表明上述位置在拉伸过程中承担更多的塑性变形。当应变增大至25%时,对比图a2与图a3,可见大部分小颗粒状奥氏体发生了明显的马氏体转变(正方形框线标识),片层状奥氏体的厚度显著降低(矩形框图所标识),而块状奥氏体未发生明显变化,只是在晶界/相界处发生局部少量马氏体转变(图3a1与图3a3中的圆形框图所标识)。对比图3b2与3b3,可见残留的块状奥氏体KAM值进一步增大(相界/晶界附近位置)。当应变增大至40%,如图3a1与3a4所示,大部分奥氏体均发生马氏体转变,残留下来的奥氏体大部分为块状或片层状,尺寸有所减小且其KAM值进一步增加。原位EBSD测试结果显示出相反的尺寸效应,即小尺寸奥氏体稳定性较低,而片层状及块状奥氏体机械稳定性较高。文献[12]报道了Fe-9Mn-3Ni-1.4Al-0.01C的相变行为,在变形过程中小晶粒要优先于大晶粒发生马氏体转变,并认为小晶粒储存层错的能力弱于大晶粒是导致上述结果的原因。Tasan[15]等用原位EBSD技术研究中锰TRIP钢相变行为,得到了类似的结果。实验结果表明,马氏体相变优先在晶界/相界处形核,随着应变的增大已转变的马氏体逐步吞噬未相变的奥氏体。

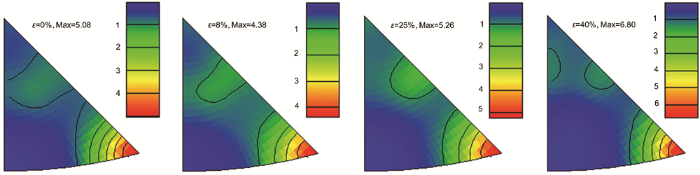

图4

图4

A68试样奥氏体拉伸过程中的反极图(拉伸轴方向)

Fig.4

IPF distribution-contour of sample A68 deformed at tensile strains of 0%~40%

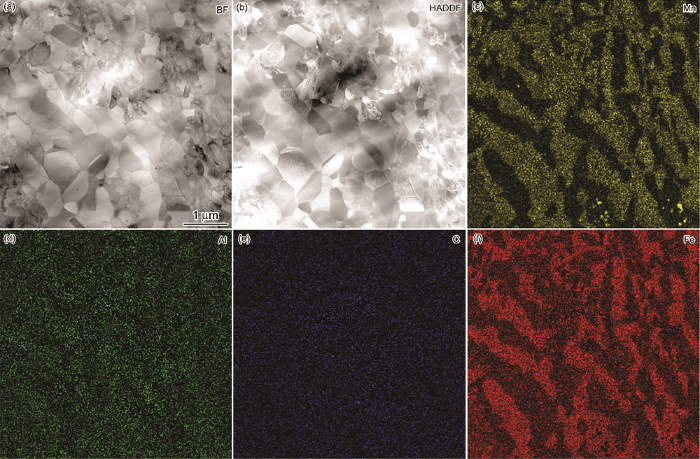

2.3 异质中锰TRIP钢元素配分行为

除了晶粒尺寸,奥氏体中的C、Mn元素含量对其机械稳定性也有重要的影响。为了探究异质中锰钢拉伸过程中相反尺寸相变效应的微观机理,用ACTEM技术对A68试样不同元素分布进行了分析,结果在图5中给出。可以看出,Mn元素在奥氏体中明显富集,而Al、Fe元素在铁素体中大量聚集。由于EDS技术的限制,图5e只能定性地反映C元素在奥氏体中亦有富集。同时,对比图5a、图5b与图5c,Mn元素在奥氏体中分布并不均匀。利用ACTEM-EDS测量不同形貌的奥氏体平均Mn含量(每种形貌取点8个以上)的结果表明,小颗粒状、大块状以及片层状奥氏体中Mn平均含量(质量分数)分别为9.53%、12.34%、13.47%。结合原位EBSD测试结果,在本文的晶粒尺寸范围内,Mn元素对奥氏体稳定性的作用比晶粒尺寸的作用大。

图5

图5

A68试样的微观结构和元素分布

Fig.5

Microstructure and element distribution map of sample A68

3 讨论

在退火过程中奥氏体形核势垒包括[17]:化学能、界面能以及弹性错配能。为了得到异质奥氏体结构,需要在奥氏体逆转变退火处理前在基体中引入不同的形核势垒。实验钢在不同制备工艺阶段的显微组织演变行为,如图6所示。热轧后中锰TRIP钢组织为马氏体,本文在热轧与冷轧工艺间引入了两相区退火处理,是生成异质奥氏体结构的关键因素之一。如图6所示,经两相区退火后热轧钢板的组织转变为片层状奥氏体与铁素体两相组织,其中奥氏体体积分数约为39.5%。需要注意的是,本文制备的冷轧中锰钢的组织与传统中锰TRIP钢(马氏体或马氏体+少量的奥氏体)有所不同。热轧退火钢板经冷轧后(约50%压下量)保留了一定量的片层状的残余奥氏体(体积分数约10%),其余的奥氏体均转化成马氏体相,最终冷轧钢板的组织为大量形变的铁素体(体积分数约60%)、相变马氏体(29%)以及残留的片层状奥氏体。由于经历过一次退火处理,C、Mn、Al等元素提前实现一次配分,残留奥氏体中C、Mn含量应为最高、相变马氏体次之,铁素体中的C、Mn含量理应最低,从而形成不同化学能势垒。此外,各相之间的相界(界面能及错配能差异性)在接下来退火过程中亦将形成奥氏体的不同形核势垒。

图6

图6

异质中锰TRIP钢各工艺阶段的微观组织演变示意图

Fig.6

Schematic sketch of the microstructure evolution behavior during various treatments of the heterogeneous medium Mn steel

当退火温度较低时(660℃),奥氏体形核和长大的条件不充分,只能在C、Mn含量较高的冷轧马氏体及其晶界/相界处完成,因此形成大量细小颗粒状奥氏体。同时,原残留的片层状奥氏体在退火过程中只在一定程度上长大,最终A66试样的奥氏体形貌主要由细小颗粒状以及细小片层状组成,其中尺寸小于100 nm奥氏体难以被EBSD所捕捉(EBSD扫描步长50 nm),因此EBSD测试奥氏体含量低于XRD测试结果。在总体上,与A68、A70试样相比,其奥氏体含量最低,因此奥氏体中的C、Mn含量相应最高,导致过高的奥氏体稳定性,造成在拉伸过程中未能发生马氏体转变。当退火温度为680℃时,奥氏体形核与长大条件适宜。奥氏体在C、Mn含量较高的马氏体及其晶界/相界处优先形核并发生一定程度的长大,最后形成块状奥氏体。此类奥氏体继承其母系马氏体中较高的C/Mn含量(经过一次退火配分处理),尽管尺寸较大但是其稳定性较高。同时,由于退火温度适宜在C、Mn含量较低的铁素体中(晶界/相界或位错处)奥氏体也形核但是较晚,长大不充分,最终形成C、Mn含量较低的颗粒状奥氏体,稳定性低于块状奥氏体。而原片层状奥氏体在厚度方向上呈现一定程度的长大,最终形成不同形貌、不同尺度、不同C/Mn元素含量的异质奥氏体组织。由于上述奥氏体稳定性的差别,在拉伸过程中能在不同应变范围内连续发生马氏体相变,从而实现了强度与塑性良好匹配。当退火温度较高时(700℃)奥氏体形核与长大比较充分,在C、Mn含量较高的马氏体及其晶界/相界处优先形核的奥氏体快速长大并吞并较晚形核的奥氏体(铁素体晶界或位错处),形成大块状的奥氏体。而原残留奥氏体由于在宽度方向上的界面能大于长度方向,最终沿着厚度方向长大分解形成若干大块状的奥氏体[7]。A70试样奥氏体的含量最高,因此C、Mn含量被稀释,其相对机械稳定性最差,进而在屈服后很快发生马氏体转变。

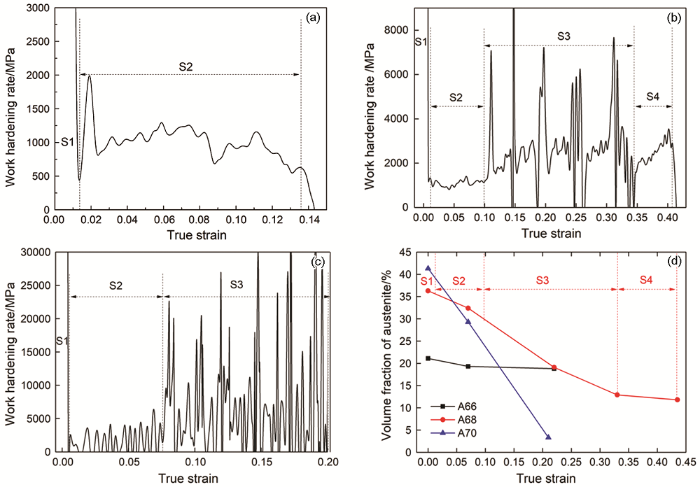

图7

图7

A66、A68和A70试样的加工硬化率和相应奥氏体含量的变化

Fig.7

Work hardening rate and the volume fraction of austenite vs true strain of A66, A68 and A70 samples

三种实验钢加工硬化率第一阶段的迅速降低与铁素体变形有关。对比可知,A66试样加工硬化率最低,其值在第二阶段主要处于500~2000 MPa,而图7d表明其奥氏体含量在整个拉伸过程中未发生明显变化,即TRIP效应不显著,从而导致其最低抗拉强度以及较低的断后延伸率。A68试样的加工硬化率可分为四个阶段,其中第二阶段相对于屈服点延伸阶段,期间奥氏体转变量不明显(由图3可知,仅部分小颗粒状奥氏体发生相变),表明A68试样奥氏体稳定性较高,此阶段加工硬化率较低。第三阶段(0.1%~0.33%)发生连续大量马氏体相变(图3),导致高的加工硬化率。第四阶段,尽管残留奥氏体转变较少(图7d),但是仍具备较高的加工硬化率。这可能与异质结构应力应变配分行为有关。对于异质结构,由于晶粒尺寸、元素含量均有所不同,在拉伸过程中不同形貌奥氏体/铁素体、奥氏体/奥氏体间将发生应力应变配分行为,在晶界/相界处产生大量几何必须位错(图3中KAM图)以协调变形不相容,因此将会产生一定的背应力,从而提高材料加工硬化能力。此外,在相界/晶界处产生的大量位错相互缠结,成为马氏体形核点。因此,在拉伸过程中位于奥氏体相界/晶界区域优先发生马氏体转变(图3)。A70试样的加工硬化率远高于A66、A68试样,由于其奥氏体稳定性较低屈服后很快发生马氏体转变直至断裂,因此其抗拉强度最高。但是,前期出现的大量尺寸较大的相变马氏体成为裂纹萌生点,最终使其延伸率较低。

4 结论

(1) 退火温度对中锰TRIP钢的微观组织有重要的影响。退火温度较低(660℃)的试样以细小颗粒状奥氏体和铁素体组织为主,奥氏体的体积分数最低。随着退火温度提高到680℃基体中的奥氏体形成异质结构,包括C/Mn含量较低的颗粒状奥氏体、C/Mn含量较高的块状奥氏体和片层状奥氏体,奥氏体的体积分数有所提高。退火温度为700℃时奥氏体以块状为主,其体积分数进一步提高。

(2) A68与A70试样获得优异性能,抗拉强度均超过1100 MPa,强塑积大于30 GPa∙%,具有异质结构的A68钢试样其抗拉强度达到1272 MPa,总延伸率为54.5%,强塑积高达69.3 GPa∙%。

(3) 在异质中锰TRIP钢的拉伸过程中马氏体相变优先在相界/晶界处发生,随着应变量的增大已转变的马氏体逐渐吞噬未转变的奥氏体,其中C/Mn含量较低的颗粒状奥氏体先发生相变、C/Mn含量较高的块状奥氏体和片层状奥氏体在较高的应变范围内发生相变,使异质结构中锰钢具有优异的性能。

(4) 在拉伸过程中奥氏体的显微织构类型并不改变,其中具有{111}面织构的奥氏体稳定性较高,经大应变拉伸后残留的奥氏体多数为{111}织构,其他类型织构的奥氏体大多转变为马氏体。

参考文献

Microstructure evolution and mechanical properties of cold-rolled Mn-Al TRIP steel with δ ferrite

[J].δ ferrite were investigated after annealed at different intercritical annealing temperature for different time. The results show that as the intercritical annealing temperature and time going up, the content of retained austenite (RA) and the product of strength and elongation (PSE) increased first and then decrease. The microstructure of the steel after annealing at 750℃ for 2 min consists of δ ferrite, intercritical ferrite and 24.7% retained austenite, which exhibited a tensile strength of 773 MPa, elongation of 39.4% and the product of strength and elongation of 30.46 GPa%. RA mainly exits at the boundaries between bulky δ ferrite and original martensite, around the recrystallization ferrite from original martensite area, and around the sub-grain boundaries inside δ ferrite.]]>

含δ铁素体Mn-Al系TRIP钢冷轧退火过程的组织性能

[J].δ铁素体的Mn-Al系冷轧TRIP钢(Fe-0.18C-6.4Mn-2.8Al)的组织和性能演变行为的影响。结果表明,随着临界区退火温度的提高和退火时间的延长,实验钢的残余奥氏体(RA)含量和强塑积呈现先增大后减小的趋势。在750℃退火2 min实验钢的组织由δ铁素体、临界区铁素体及残余奥氏体组成,其RA含量为24.7%,抗拉强度为773 MPa,断后延伸率39.4%,强塑积为30.46 GPa%。RA主要集中在粗大δ铁素体与原马氏体边界、原马氏体区域内再结晶铁素体晶界周围以及粗大δ铁素体内的亚晶界附近。]]>

Microstructure and tensile behavior of duplex low-density steel containing 5mass% aluminum

[J].

Interplay between deformation behavior and mechanical properties of intercritically annealed and tempered medium-manganese transformation-induced plasticity steel

[J].

Enhanced quasi-static and dynamic shear properties by heterogeneous gradient and lamella structures in 301 stainless steels

[J].

Extraordinary Bauschinger effect in gradient structured copper

[J].

Back stress strengthening and strain hardening in gradient structure

[J].

Combining gradient structure and TRIP effect to produce austenite stainless steel with high strength and ductility

[J].

Effects of prestrain and grain boundary segregation of impurity atoms on bake hardening behaviors of Ti+V-bearing ultra-low carbon bake hardening steel

[J].

Mechanical properties and deformation behavior in hot-rolled 0.2C-1.5/3Al-8.5Mn-Fe TRIP steel: The discontinuous TRIP effect

[J].

Performance improvement of steels through M3 struture control

[J].

高性能钢的M3组织调控理论与技术

[J].本文介绍国家重点基础研究发展计划(973计划)—“高性能钢的组织调控理论与技术基础研究”项目的研究目标和内容。该项目以提高钢的服役安全性为目标,研究提高钢的性能之组织调控理论和技术。研究内容包括了温度和应力作用下的亚稳奥氏体相变机理、相变过程中碳扩散、相变组织多尺度特征、相变组织在温度—应力—腐蚀作用下的稳定性、以及获得高洁净度和高均匀度钢坯的化学冶金学和凝固技术基础。建立以“多相(Multi-phase)、亚稳(Meta-stable)、多尺度(Multi-scale)”(简称M3)为特征的组织调控理论,形成以第三代低合金钢、第三代汽车薄板钢和第三代马氏体耐热钢为代表的高性能原型钢技术,为大幅度提高建筑设施、汽车、能源装备的服役安全性奠定钢铁材料技术基础。

Spectral TRIP enables ductile 1.1 GPa martensite

[J].

In-situ SEM observation of phase transformation and twinning mechanisms in an interstitial high-entropy alloy

[J].

Design of a novel Mn-based 1GPa duplex stainless TRIP steel with 60% ductility by a reduction of austenite stability

[J].We report on the microstructure, texture and deformation mechanisms of a novel ductile lean duplex stainless steel (Fe-19.9Cr-0.42Ni-0.16N-4.79Mn-0.11C-0.46Cu-0.35Si, wt.%). The austenite is stabilized by Mn, C, and N (instead of Ni). The microstructure is characterized by electron channeling contrast imaging (ECCI) for dislocation mapping and electron backscattering diffraction (EBSD) for texture and phase mapping. The material has 1 GPa ultimate tensile strength and an elongation to fracture of above 60%. The mechanical behavior is interpreted in terms of the strength of both the starting phases, austenite and ferrite, and the amount, dispersion, and transformation kinetics of the mechanically induced martensite (TRIP effect). Transformation proceeds from austenite to hexagonal martensite to near cubic martensite (gamma -> epsilon -> alpha'). The epsilon-martensite forms in the austenite with an orientation relationship close to Shoji-Nishiyama. The alpha'-martensite nucleates at the intersections of deformation bands, especially epsilon-bands, with Kurdjumov-Sachs and Nishiyama-Wassermann relationships. The ferrite deforms by dislocation slip and contains cell substructures. (C) 2011 Acta Materialia Inc. Published by Elsevier Ltd.

Smaller is less stable: Size effects on twinning vs. transformation of reverted austenite in TRIP-maraging steels

[J].Steels containing reverted nanoscale austenite (gamma(RN)) islands or films dispersed in a martensitic matrix show excellent strength, ductility and toughness. The underlying microstructural mechanisms responsible for these improvements are not yet understood, but are observed to be strongly connected to the gamma(RN) island or film size. Two main micromechanical effects are conceivable in this context, namely: (i) interaction of gamma(RN) with microcracks from the matrix (crack blunting or arresting); and (ii) deformation-induced phase transformation of gamma(RN) to martensite (TRIP effect). The focus here is on the latter phenomenon. To investigate size effects on gamma(RN) transformation independent of other factors that can influence austenite stability (composition, crystallographic orientation, defect density, surrounding phase, etc.), a model (TRIP-maraging steel) microstructure is designed with support from diffusion simulations (using DICTRA software) to have the same, homogeneous chemical composition in all gamma(RN) grains. Characterization is conducted by in-situ tension and bending experiments in conjunction with high-resolution electron backscatter diffraction mapping and scanning electron microscopy imaging, as well as post-mortem transmission electron microscopy and synchrotron X-ray diffraction analysis. Results reveal an unexpected "smaller is less stable" effect due to the size-dependent competition between mechanical twinning and deformation-induced phase transformation. (C) 2014 Acta Materialia Inc. Published by Elsevier Ltd.

Novel ultra-high-strength (ferrite+austenite) duplex lightweight steels achieved by fine dislocation substructures (Taylor lattices), grain refinement, and partial recrystallization

[J].

The role of crystal misorientations during solid-state nucleation of ferrite in austenite

[J].AbstractThe role of grain and phase boundary misorientations during nucleation of ferrite in austenite has been investigated. Electron back-scatter diffraction (EBSD) was performed on a high-purity iron alloy with 20 wt.% Cr and 12 wt.% Ni with austenite and ferrite stable at room temperature in order to identify the crystallographic misorientation between austenite grains and between ferrite and austenite grains. It is observed that the specific orientation relationships between ferrite and austenite play a dominant role during solid-state nucleation of ferrite. Ferrite grains nucleate on grain faces independently of the misorientation between austenite grains, although random high-angle grain boundaries have a slightly higher efficiency. Different types of nucleation mechanisms are found to be active during ferrite formation at grain faces. A slight deformation of the austenite matrix was found to triple the number of ferrite nuclei during isothermal annealing.]]>