磨粒刮擦诱导单晶镍微结构演化与塑性去除行为的纳观分析

Microstructure Evolution and Plastic Removal for Single Crystal Nickel Induced by Particle Scratching: Atomic Simulation Method

磨粒刮擦诱导单晶镍微结构演化与塑性去除行为的纳观分析 |

| 陈晶晶, 邱小林, 李柯, 袁军军, 周丹, 刘亦薇 |

|

Microstructure Evolution and Plastic Removal for Single Crystal Nickel Induced by Particle Scratching: Atomic Simulation Method |

| CHEN Jingjing, QIU Xiaolin, LI Ke, YUAN Junjun, ZHOU Dan, LIU Yiwei |

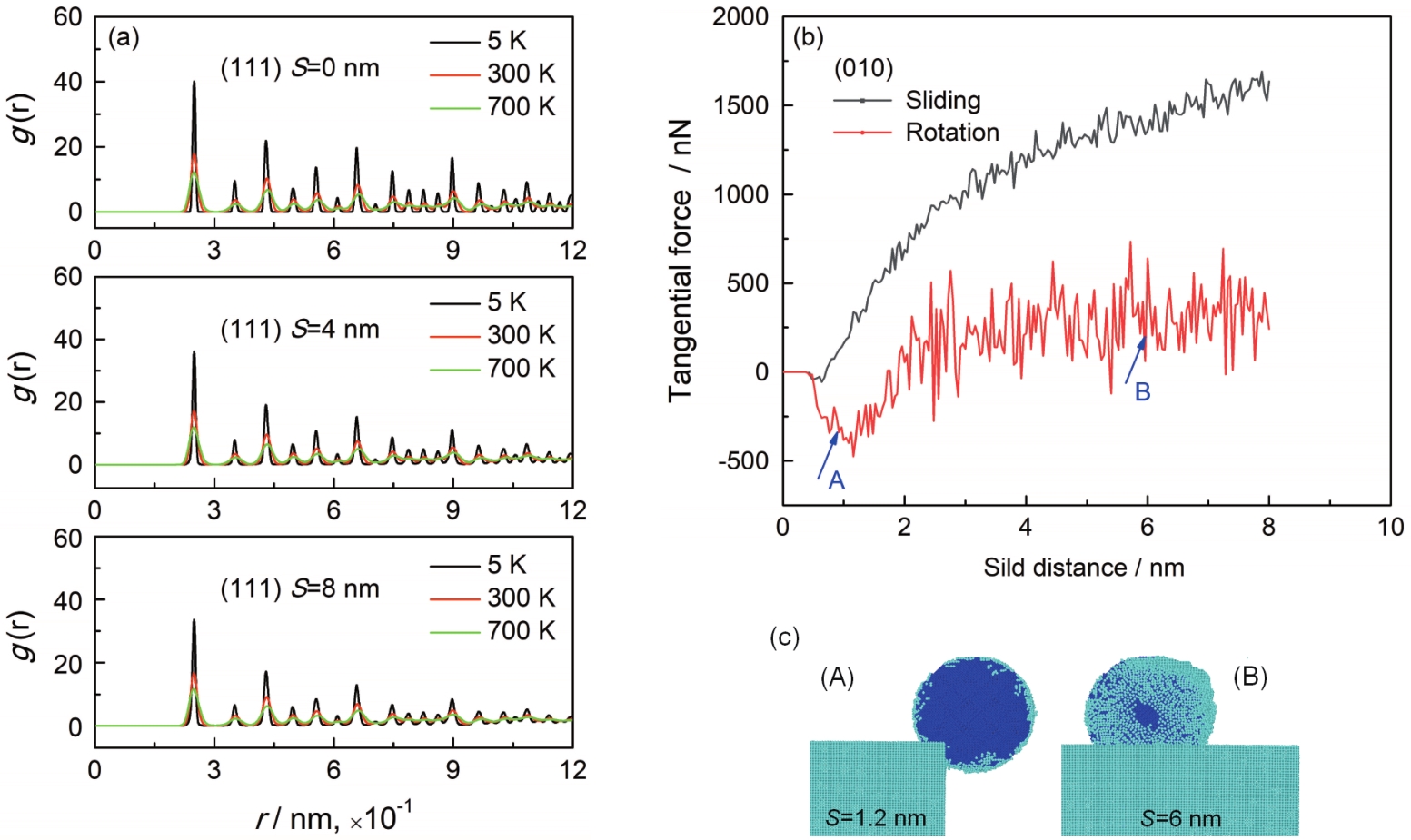

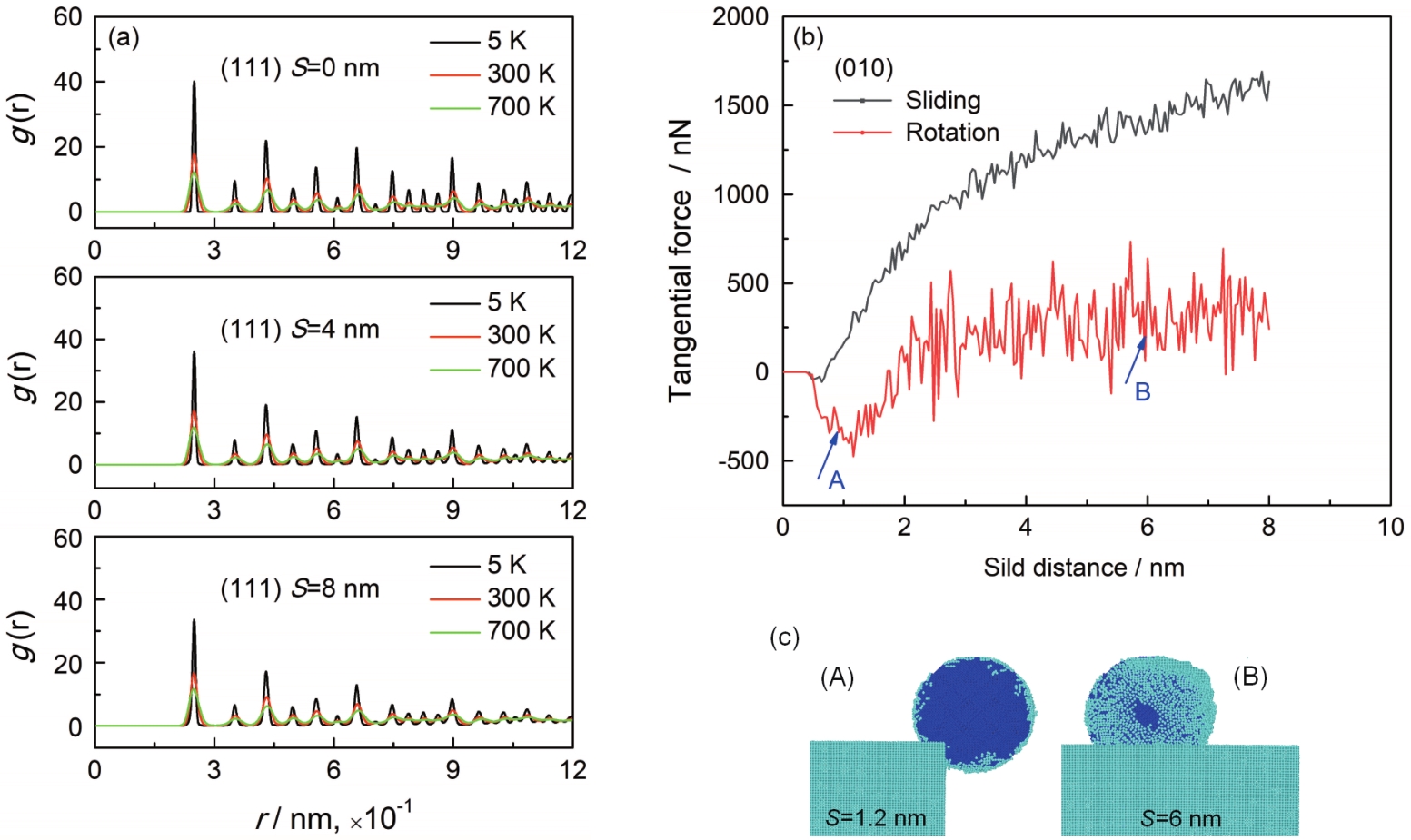

| 图5 在不同温度下经磨粒刮擦后单晶镍的径向分布函数、在滑动和滚动作用下切向力的演化以及滚动刮擦距离为1.2 nm和6 nm时的磨粒形貌 |

| Fig.5 Radial distribution function of single nickel after scratching at different temperatures (a), evolution of tangential forces under sliding and rolling actions (b) and morphologies of abrasive particles when scratching distance are 1.2 nm and 6 nm (c) |

|